In the world of bespoke furniture, few pieces command attention and spark conversation quite like an epoxy resin and walnut wood slab table. This unique fusion of organic material and modern synthetic creates a stunning functional art piece, blending the timeless warmth of wood with the sleek, contemporary appeal of resin.

The Allure of Walnut Wood

At the heart of these tables is the walnut slab itself. Prized for its durability and breathtaking beauty, walnut wood is characterized by:

-

Rich, Dark Tones: Its heartwood ranges from a deep, chocolate brown to a purplish-black, offering a dramatic and sophisticated backdrop.

-

Striking Grain Patterns: Walnut boasts elegant, often swirling grain patterns that tell the story of the tree's life. Natural features like knots, cracks, and burls are not flaws but highly sought-after characteristics that add unique character.

-

Strength and Stability: Despite its beauty, walnut is a hard, strong wood, making it an excellent choice for a durable table surface that can last for generations.

Pls click Youtube video:https://www.youtube.com/shorts/lOg9qlkSK0Q

Pls click tiktok video:https://www.tiktok.com/@woodyoulikewood/video/7548282306662812936

The Magic of Epoxy Resin

Epoxy resin is a high-performance, clear liquid that, when mixed with a hardener, cures into a solid, glass-like plastic. Its role in these tables is multifaceted:

-

Stabilization: Many live-edge slabs have natural cracks, voids, or checks. Instead of cutting these away, artisans pour epoxy to fill them, preserving the wood's original, organic shape while making the table structurally sound and usable.

-

Creative Canvas: Epoxy is where artistry comes into play. It can be left perfectly clear to showcase the wood's natural edge, or tinted with pigments and dyes. Popular choices include deep blues and greens to mimic river tables, bold blacks for a modern contrast, or even metallic tones for a touch of glamour.

-

Durability and Function: Once cured, the epoxy creates an incredibly hard, non-porous, and seamless surface. It is highly resistant to moisture, heat, scratches, and stains, making it practical for everyday use. The surface is typically food-safe and easy to clean when properly finished.

The Craftsmanship Process

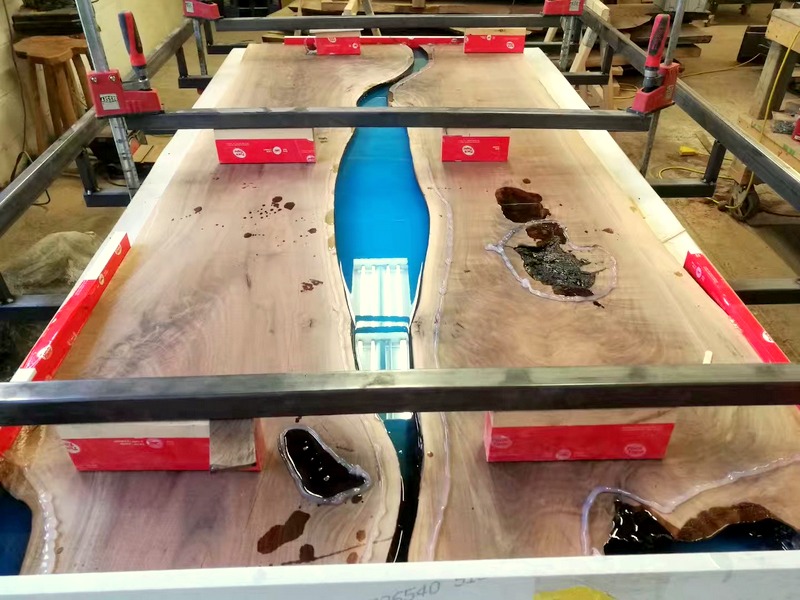

Creating these tables is a labor-intensive process that requires skill and precision:

-

Selection and Preparation: The perfect walnut slab is chosen, dried, and sanded.

-

Molding: The slab is placed in a custom-built mold, which is meticulously sealed to prevent leaks.

-

Pouring: The mixed epoxy is poured slowly, often in multiple layers, to fill voids and create the desired design effect. Bubbles are removed with heat or pressure for a crystal-clear finish.

-

Curing: The piece is left to cure for several days until the epoxy is rock-solid.

-

Finishing: The entire piece is sanded through progressively finer grits—a process that can take days—to achieve a perfectly level surface. Finally, it is polished to a high-gloss, satin, or matte finish, revealing the deep luster of both the wood and the resin.

Why Choose One?

An epoxy resin walnut table is more than just a place to dine or work; it is a centerpiece. It suits a variety of interiors, from rustic and industrial to minimalist and ultra-modern. Each table is utterly unique, a captured moment of natural history enhanced by human creativity.

It represents a perfect balance: the warmth and history of nature seamlessly integrated with the cool, innovative spirit of modern design.

Follow Us 14years+ Solid Wood Furniture Manufacturer.

Alibaba website:https://woodyoulike.en.alibaba.com/

Official website:https://www.woodyoulike.org/

Youtube

https://www.youtube.com/@hijackychan

https://www.youtube.com/@woodyoulikewood

TikTok

https://www.tiktok.com/@woodyoulikewood

Contact

Attn: Jacky Chan

Whatsapp/phone:+86-18221567891

Email: info@chinaworktops.com

中文

中文 English

English Français

Français Deutsch

Deutsch Português

Português 日本語

日本語 한국어

한국어